Sliding horse stalls are the most popular design in horse barns. Sliding stall doors operate on a sliding track in contrast to hinged stall fronts (Euros). For this reason, sliding stall fronts provide a major space saving advantage.

Our sliding horse stall fronts are built with only the best raw materials including 100% USA galvanized steel. Our materials and designs are then fabricated by certified welders and craftsmen. Our sliding track system is the best in the industry with a self-cleaning design and strong Delrin rollers. This means that your sliding horse stall doors will operate smoothly years after your purchase.

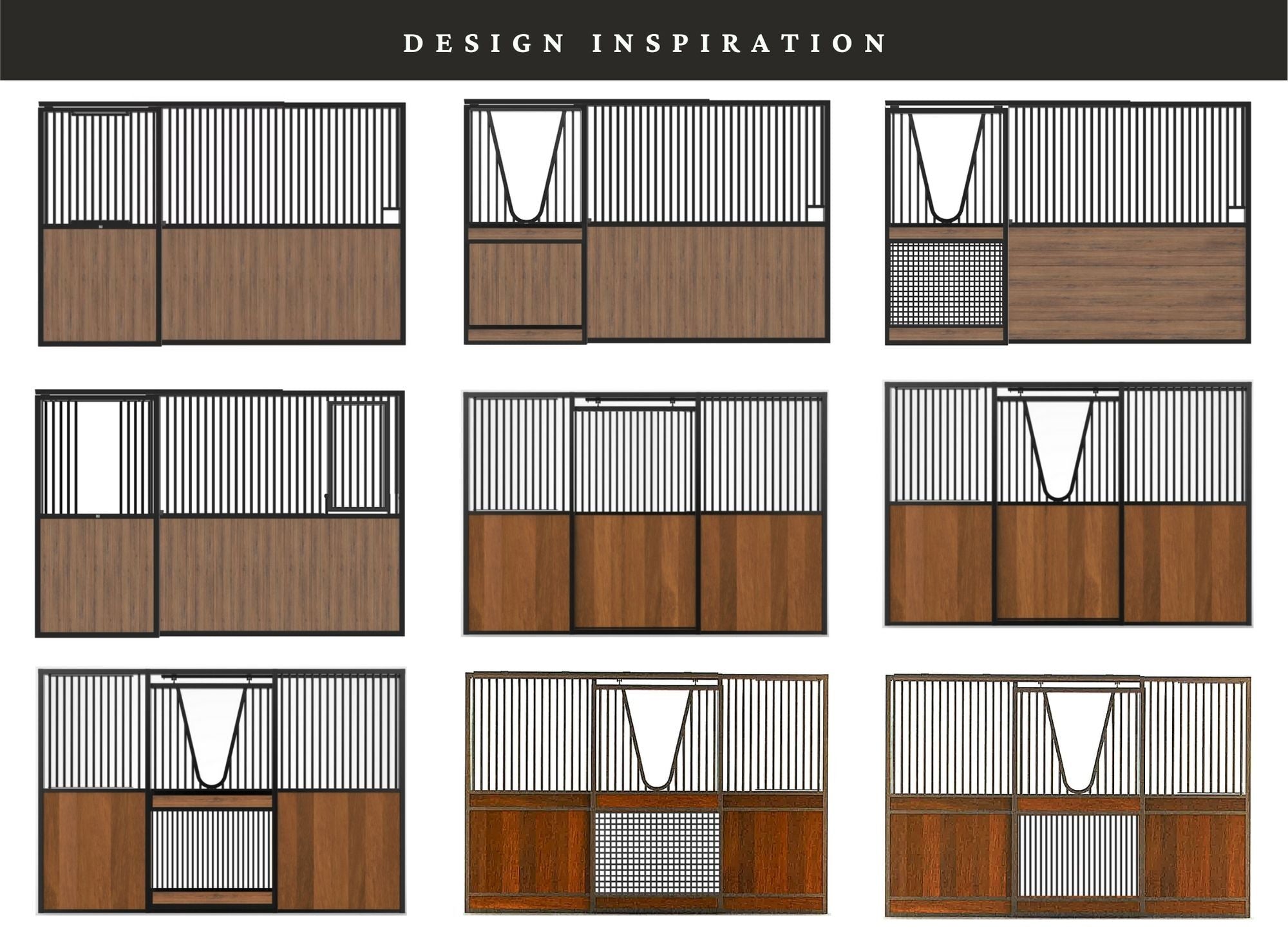

All of our horse stalls are built to order. This means that there is no “standard” design. Our sliding horse stall fronts can be dressed up with brass accents, arches, and yokes. In contrast, they can also be designed to have a simple style and an emphasis on function. Choose from various options and styles to create a horse stall design that meets your design and lifestyle goals.

Trolleys

Trolleys

Track System Package

Track System Package

Pin Lock Latch System

Pin Lock Latch System

Door Stop and Door Guide

Door Stop and Door Guide

We are located just outside Washington D.C., but our customers are all over the world. We custom build and ship our custom horse stalls across the world.

Our expert logistics team can coordinate the best transportation to help your stall equipment reach your barn via the quickest, most efficient method. This applies to any domestic deliveries within the United States and even for international deliveries across the world.

The actual thickness of the steel sheet is indicated as a unit of measurement referred to as “gauge.” The rating for steel gauge may seem backward:the smaller the number, the thicker the steel. For example, 14-gauge will be thicker than 16-gauge.

We use a variety of different gauges on our products. However, the vast majority of our Sliding Horse Stall Front systems use 14-gauge American steel for steel framing and the steel tubing. Rest assured, your American Stalls equipment is built to last.

All of our American Stalls products are built with longevity in mind. We use only the very best raw materials including pre-galvanized steel for our structural components. We then exclusively use pre-galvanized steel, stainless steel, and/or aluminum on all hardware (i.e. hinges, latches, bolts, etc).

Our pre-galvanized steel frames, tubing, and hardware all undergo a strict quality control process before powder coating. For example, we use a zinc-prime paint coat on all welds for any projects going to high salt exposure areas such as coastal Florida.

We believe this is a significant differentiator where we take multiple steps to clean and prime our pre-galvanized products prior to powder coat. We then powder coat each component from experts who have years of experience. Lastly, we utilize an industry-leading TGIC-polyester based powder coat finish that is tested for ultimate performance. Rest assured, your American Stalls products will stand the test of time.

Yokes are very popular across our Sliding Horse Stall Door designs. The Yoke is a custom cut out on the top half of a horse stall door.

This Yoke "opening" offers your horse the oppurtunity to stick their heads into the aisle to see fellow horses and people. While a yoke might not be the best option for each horse since temperments and facilities will vary. That being said, we offer many options in yokes.

Our Open Yoke is the most popular among clients. This is simply a cut-out in the shape of a v-shape or a rectangle. This is open at all times and is best suited for well-mannered horses that get along with other horses and riders.

We also offer our clients the ability to close their yokes with Yoke-Fill Pieces and Hinged Fold-Down Systems. Both options allow for added functionality for our Sliding Horse Stalls.

This is a great question! Many Sliding Horse Stalls on the market are difficult to move as the years go on. This is because the track systems might not be well-suited for a barn enivronment where dust builds up. To prevent this, our track systems feature a self cleaning design which ensures no build up within the track that might obstruct movement.

Secondly, most track systems on the market use cheaper plastic trolleys (also known as rollers). These plastic trolleys are low quality and will deterioate as they continue to roll against dust, debris, and other build up in the track. Instead, we use heavy-duty Delrin balls as our trolleys which ensure your Sliding Horse Stalls will effortlessly glide for years to come.

We prioritize simple, functional design in all of our products. That means simplicity and practacility for the end user. That also means simple products that are easy to install by our clients, general contractor, and builder partners.

Once you take delivery on your custom Sliding Horse Stalls, your Project Manager will share precise, detailed Installation Instructions. Our Instructions include in-depth visuals, videos, and helpful instructions. We are also always available via phone call or FaceTime to asssit our clients with any real-time questions.

We offer our clients two options: our Flip Latch and our Pin Lock Latch. Our Pin Lock Latch is our best-selling latch, but our flip latch is sometimes used in facilities who have a personal preferance. Our Pin Lock Latch features the highest quality materials including 304 stainless steel and aluminum. These materials ensure durability, strength, and overal longevity.

We always recommend our Sliding Horse Stalls and Pin Lock Latch because it promotes safety in your barn. For example, in the case of an emergency, our design allows you to quickly unlock each stall door – allowing you to go from one stall to the next.

You absolutely can purchase the horse stall door, grillwork, and hardware – instead of the entire Stall Front System. We wrote a helpful article to help provide more clarity to clients about the possibilities. Read more here at Fully Welded Horse Stalls versus Kit Horse Stalls.

Compared to European (hinged) stall fronts, sliding sliding fronts allow our clients to save valuable space. This is because the sliding stall door slides against the stall front panel or existing horse stall front. Hence, the door doesn’t swing outward into the barn aisle like a hinged horse stall door. This space-saving feature makes sliding doors a perfect fit for busy facilities including horse boarding barns, training barns, and large venues.

We offer a five-year limited warranty on our Sliding Horse Stalls which is effective towards workmanship. We offer an industry-leading lifetime warranty on our track system.

Yes, our clients do often require equipment to unload your American Stalls purchase from the delivery truck. Our team will communicate the necessary freight protocol and required equipment based on the purchased products.

For Sliding Horse Stall equipment, we require forklift (or similar equipment) that has the ability to handle 5,000 lbs with 6 feet forks.